In the biofuels industry power reliability is not an exception. For a customer in Fair Oaks Indiana had a common issue most farms face, power failures. Over the course of a year the customer spent thousands on replacing PLCs, IO cards, HMIs and other electrical components. As the power spikes persisted reliability plummeted along with revenue as operations were unable to restart the plant with failed DCS components.

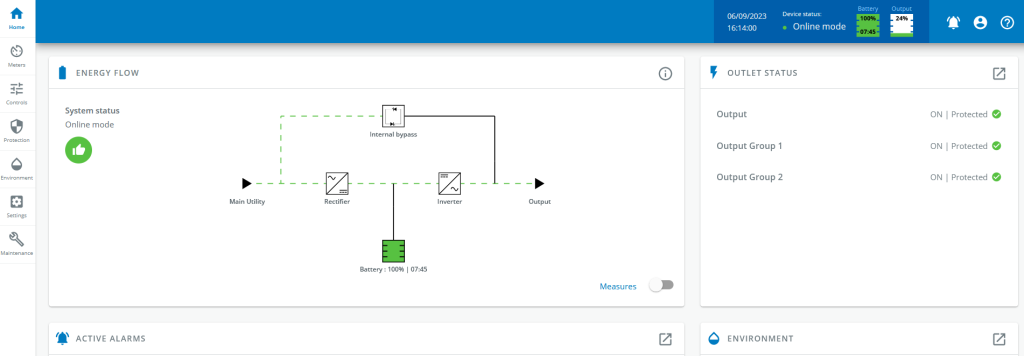

As the customer main DCS support Helle Engineering developed a project to address the issue. The design consisted of 2 different rated panels NEMA4 for outdoor use and NEMA12 for indoor use. Both panels were custom designed to hold an Eaton 9SX UPS and external batteries. The NEMA4 panel had an AC system for climate control while under the Class 1, Div 2 area classification. The NEMA12 panel had a cooling fan and filter system. Both panel designs were used for providing 12 hours of uninterruptible power for remote DCS control panels. These UPS systems saved them thousands of dollars on protecting DCS equipment and increased the reliability of the DCS system. Increases in production are now occurring because operators can restart the plant in a timely manner after a temporary loss of the 480VAC bus.

All UPS systems had a common trouble and temperature alarm wired back to the control system. For this project our I&E services installed 5 UPS panels, 3 outdoor and 2 indoor. Each UPS system could power 4 separate 120VAC circuits. The units also included an Ethernet card module that allowed the customer to access a Web interface for remote monitoring and management.